|

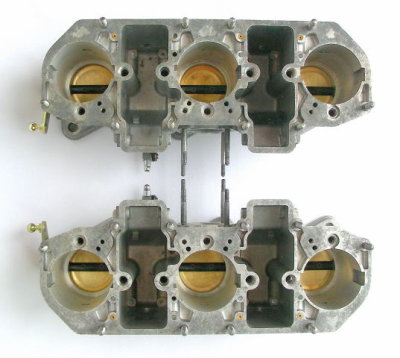

Weber Housing:

Machine one pair Weber housings. Resurface bases, lap barrels, install new

machined brass bushings, verify all passages clear, machine and fit throttle

plates, replace throttle arm ball pins, install new 8mm throttle shafts.

$2650

Instructions:

Disassemble and send empty housings with throttle shafts, throttle plates,

throttle arms with stop screw. Please pack well.

Weber Carburetors

Complete: All of the above plus completely rebuild, plate applicable hardware,

verify all jets are true to size, OEM finishes where appropriate, bench test,

set pumps/floats, ready to run. $4325

New vent tubes

installed on top covers, long or short. $140/set of 4

Instructions:

Send completely assembled. Actuate pumps to remove as much fuel as possible,

Send with air funnels attached ONLY for IDS carburetors in order to protect the

enrichment nozzles, otherwise do not send funnels. Please pack well.

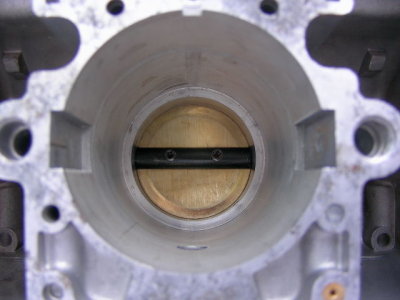

Worn bushings are replaced with machined brass

bushings at each end of the housing. Most also require an

internal bushing for the long shaft.

If the original throttle plates are not bent, we

can increase their overall diameter and then machine the plate

to the bore size with the correct beveled angle. If the plates

are bent, or at the customer's request, we will machine new

throttle plates from metric spec sheet brass. |

![]()